Making measures for a sustainable future

An analyzing tool from Sandvik Coromant helps customers reduce their energy consumption and carbon emissions based on data.

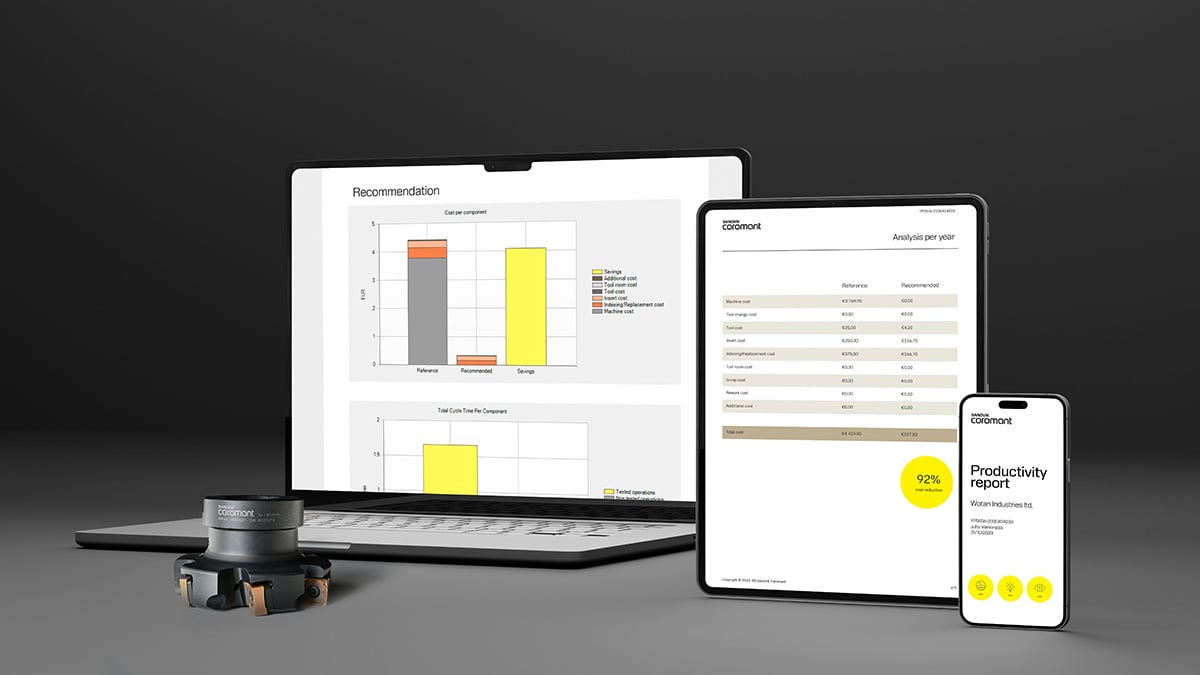

The Productivity Analyzer, introduced two decades ago, has proved to be a success. In 2023 alone, it helped customers save nearly two million production hours. It has now been upgraded with the new module, Sustainability analyzer, where customers can measure their energy consumption and CO₂ emissions.

The Productivity Analyzer, introduced two decades ago, has proved to be a success. In 2023 alone, it helped customers save nearly two million production hours. It has now been upgraded with the new module, Sustainability analyzer, where customers can measure their energy consumption and CO₂ emissions.

“We believe in unlocking potential with data,” says Patrik Eurenius, Head of Sustainability and EHS at Sandvik Coromant. “Successful manufacturers are those who recognize data as a primary asset for their company and use the analyzer to make the right decisions. Through the insights from our Productivity Analyzer, customers can better understand the impact of their production and how to make efficiency improvements.”

Benefits of integrating data-driven tools in manufacturing

Illustrating the direct and indirect benefits of smart machine tooling, such as increased productivity, higher return rates and increased machine utilization, the Productivity Analyzer provides a detailed breakdown of a customer’s tool use and its impact on their operations. Data is delivered through a reporting system, which outlines the exact savings customers can make by using Sandvik Coromant tools, and also provides suggestions for further improvement.

“Despite the importance of reducing energy consumption and carbon emissions, sustainability metrics haven’t been held in the same regard as other business metrics. That is about to change with the new sustainability measuring features that we have developed,” says Eurenius.

How Sandvik Coromant's analyzer operates

The sustainability data provided by the analyzer includes energy consumption per component and the amount of CO₂ emissions generated per year. The sustainability data is based on parameters such as the amount of energy input on the spindle used for cutting processes, the price of energy in the manufacturer’s region and the corresponding carbon intensity, and the power required to run a machine outside of its normal cutting requirements. This data is sent to the CoroPlus® Tool Guide, where calculations are made before being sent back to the Sustainability Analyzer.

Helping customers with data-driven decisions

“We can then give customers exact figures on their energy consumption, energy cost savings and CO₂ emissions,” says Eurenius. “Equipped with this data, they can then make data-driven informed decisions on how to reduce their carbon footprint. Offering customers the ability to measure the climate impact from their machining operations will build a foundation for a more sustainable future.”