Circularity

We will drive circularity and resource efficiency, doing better with less and working towards circular value chains.

We are committed to playing our part in building a global economy based on circular business models. By minimizing waste and finding new ways to capture sustainable materials and products within closed loops, we can reduce carbon emissions and bring environmental benefits for land and water. And, in the case of critical minerals, circularity will help to meet the demand caused by the energy transition.

Our goal is to have at least 90% materials circularity for packaging, products and waste by 2030 and we expect the same of our key suppliers. We are building circularity and resource efficiency into our business in a number of different ways.

In our own operations, we are working to increase the share of waste that is reused or recycled. In countries without strong waste management infrastructure, we collaborate with partners to identify alternatives to landfill. We are rethinking packaging, looking at whether a product needs packaging and, if so, what is the most environmentally efficient option.

Progress during the last years

We maintained our continuous work as well as to run projects at our manufacturing sites to reduce, reuse and recycle waste in the factories.

Sourcing of low-carbon materials and circularity/ecodesign initiatives are other integral parts of our transition. In 2024, we launched the industry’s first dump box for mining trucks manufactured using SSAB Zero™ steel, which is steel made using recycled steel (scrap) and fossil-free energy. We create circular business models to keep valuable materials in circulation, for instance by running buyback/recycling programs for our used tools and carbide drill bits. Our Bergla® tungsten carbide powder is made entirely of recycled material. We run reconditioning programs for our solid round tools and refurbishment programs to prolong the life of our mining and rock processing equipment.

Increased waste circularity

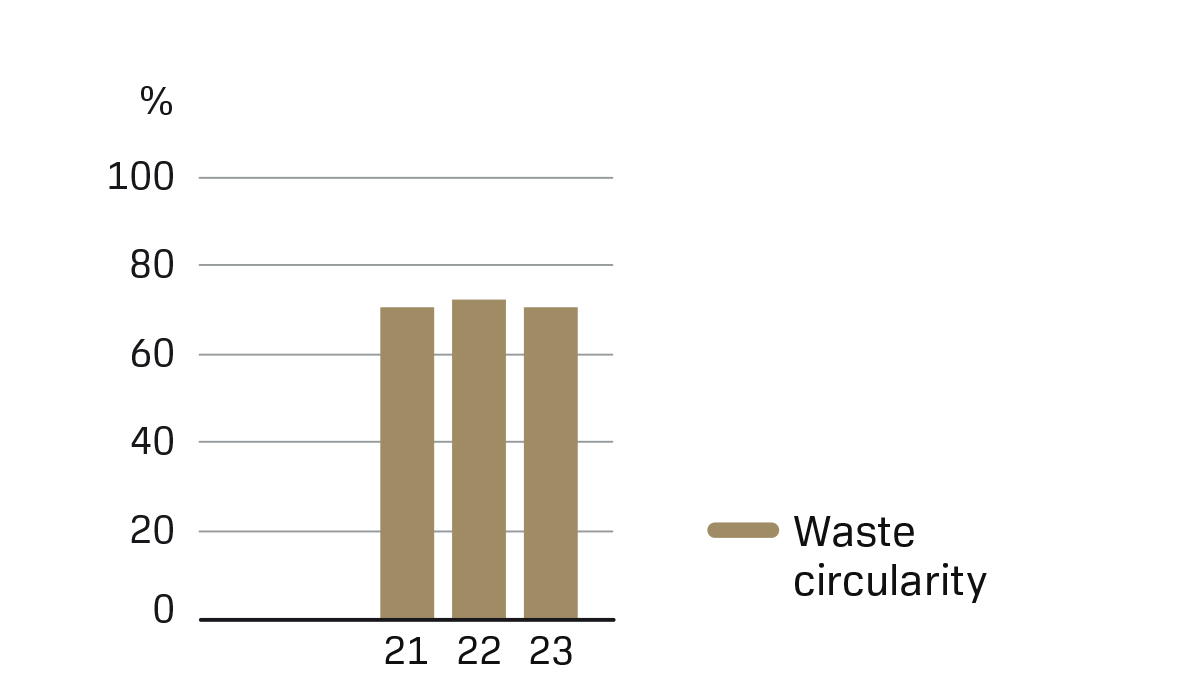

Our target* is to increase our waste circularity to 90 percent by 2030. In 2024, we achieved 74 percent waste circularity. Circular waste is defined as reuse and recycling. In circularity rate reporting, we exclude tailings, digestion sludge, foundry sand and slag because we assess that it is not feasible in the foreseeable future to take further actions to avoid sending these fractions to landfill. Total waste increased by 12 percent to 371 ktons, primarily driven by an increased amount of tailings, digestion sludge and slag.

The table and graph show the waste circularity in per cent for 2021–2024.

| 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|

| 65 | 74 | 73 | 74 |

Environmental footprint

In our annual report, you can read about our environmental footprint and progress against the targets.

Go to the note for our environmental footprint in the Annual Report

Circular business models

We are constantly advancing the productivity and automation of our equipment and services and investing in technologies that enhance resource efficiency. We are increasing the amount of circular materials in our products.

A circular economy begins at the design stage. We are committed to improving material and resource efficiency as part of all development projects and our ambition is to design our products for refurbishment, remanufacturing or recycling. The objective is to maintain materials and products at their highest value in use for as long as possible. To facilitate this, we are creating circular business models to keep valuable materials in circulation. Other innovations include developing sustainable materials for additive manufacturing.